Automated Process Cycle • Simple to Use • Oil Condition Monitor

CASE STUDY:

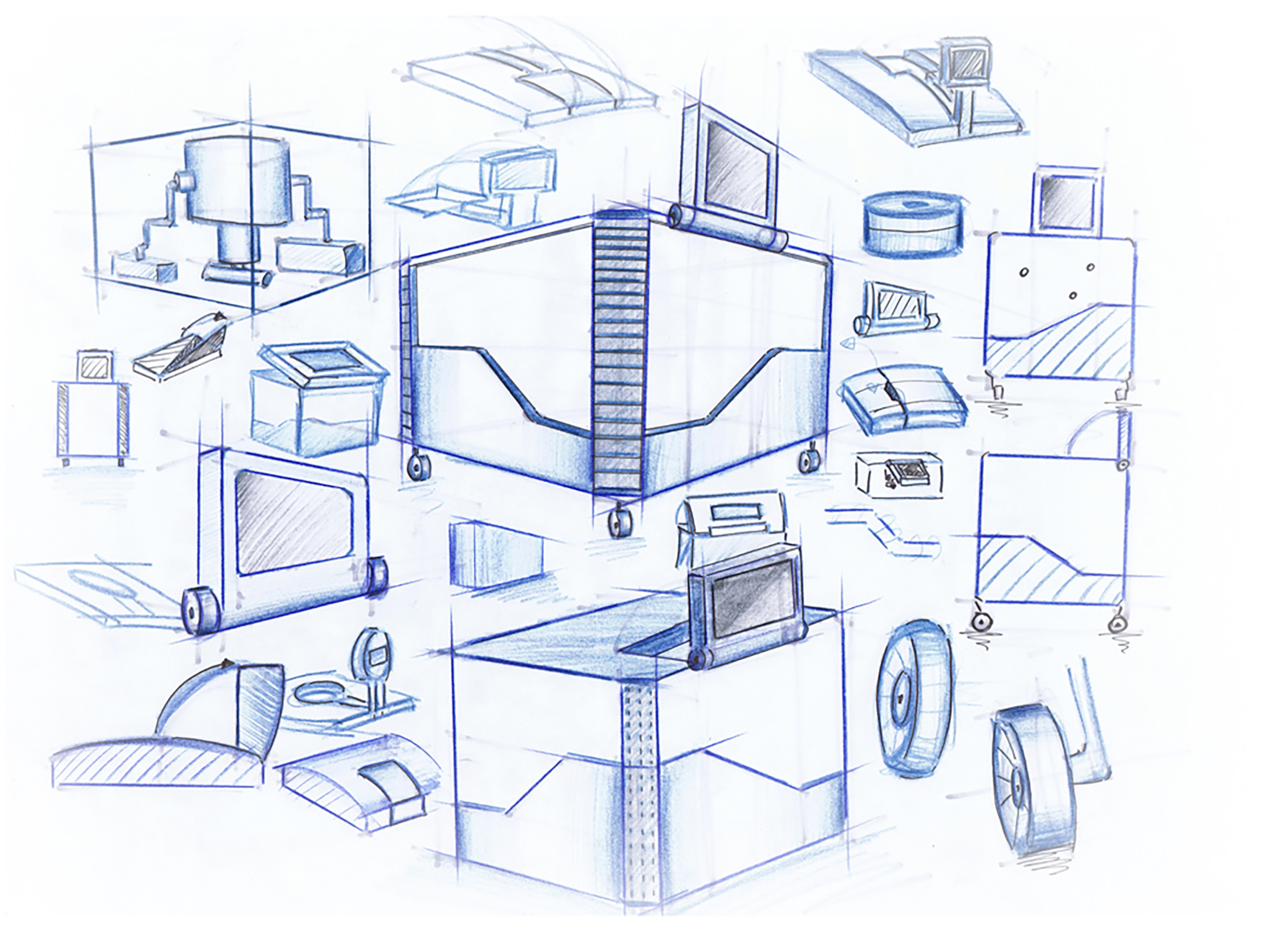

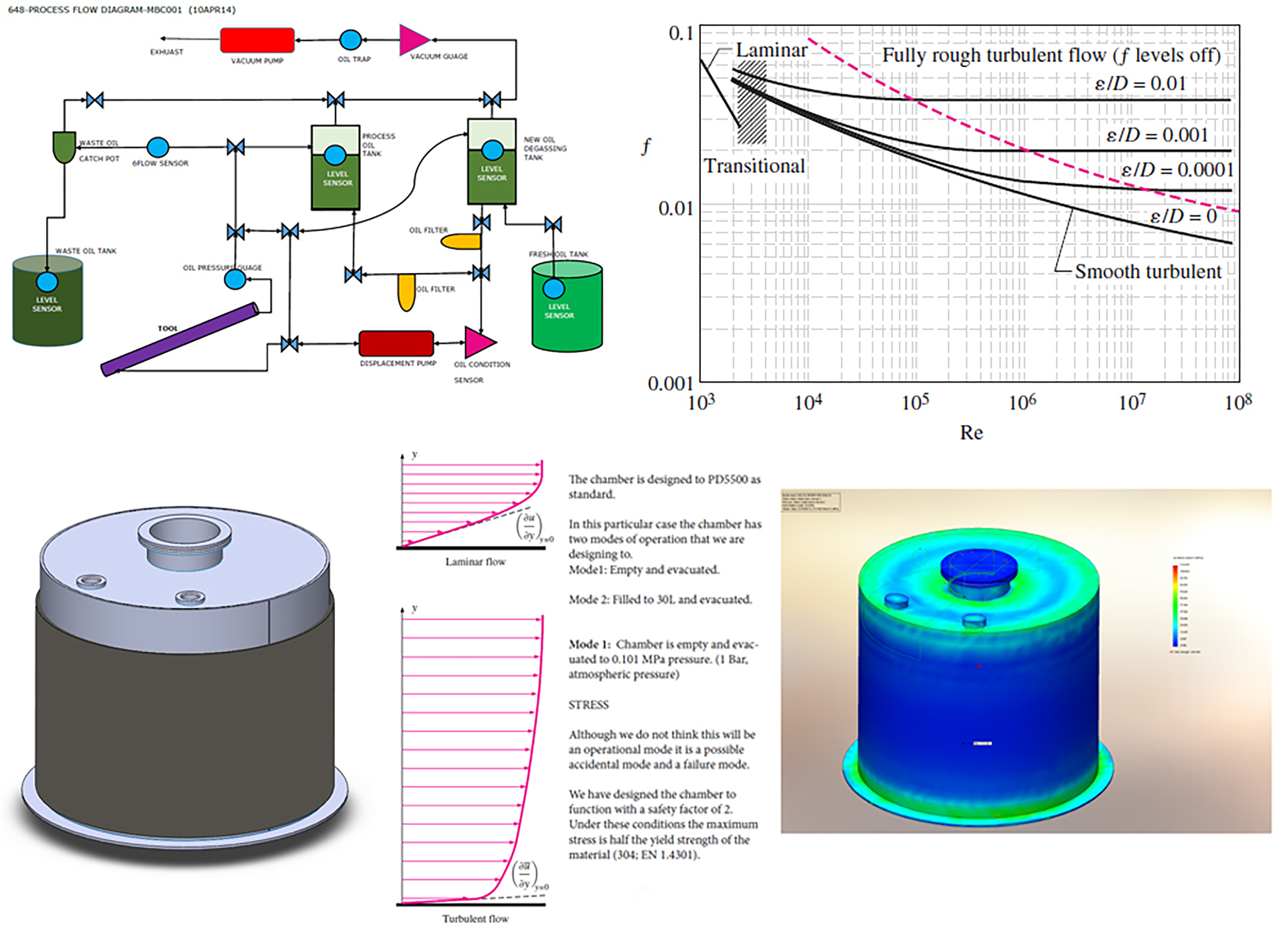

Contracted to design and manufacture an oil degassing system, for the purposes of conditioning hydraulic oil used within a drill tool used for the extraction of crude oil and gas.

The design brief was to provide an innovative automatic process for conditioning of new oil prior to filling a new drill tool. It also had to be capable of removing used oil from a drill tool.

The system cleans and monitors the condition of the used oil to assess its suitability to be reused.

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

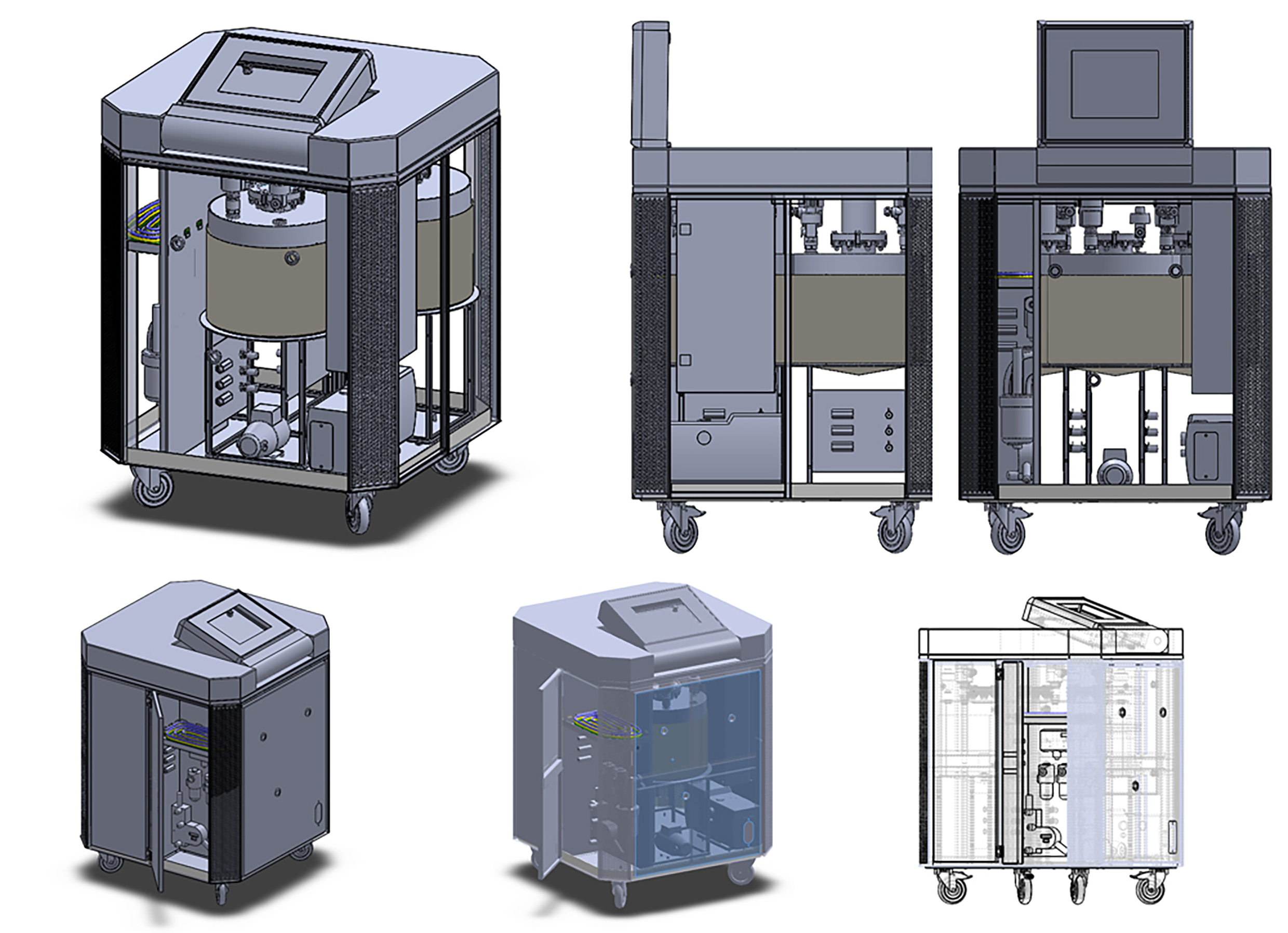

Specification

Vacuum Chamber: Vertical stainless Steel

(450mm dia. x 400mm depth) with 10mm dia. viewing port

Vacuum Pump: Pfeiffer Pascal 1005SD rotary vane pump

Oil Transfer Pump: Haight 5U gear pump, 13 bar, 15 slpm

System Cooling: Natural convection

Control System: PLC controlled

- Automatic and Manual control capability

- Hydac oil condition monitor

- Recipe driven automatic operation

- Data capture/storage

- System safety interlocks

Power Supply: 220-240V 50Hz, 1 Ph

Space Envelope: 0.96m(w) x 1.1m(d) x 1.8m(h)