Over the past years, forensic VMD® has been completely transformed due to West Technology Forensics’ development of the systems and the technique. There are many misconceptions and myths around VMD®, so to help dispel some of them, here are our top 20 questions we’re regularly asked.

If you have any of your own, please feel free to send us an email to forensics@west-technology.co.uk

1. What is Forensic Vacuum Metal Deposition (VMD®)?

The coating of an item with atomic layers of metal in a vacuum chamber to visualise latent fingerprints.

2. What types of evidence can be processed with VMD®?

A huge range of non-porous, semi-porous and porous items e.g., flexible plastic packaging, paper, plastic bottles, cell phones, glass, fabrics, firearms, fired ammunition, knives, thermal paper, wood, currency, IEDs, latex gloves etc. The UK Home Office recommend forensic VMD® for the following:

- Items exposed to high temperatures (the only process recommended for temperatures as high as 900°C or 1652°F)

- Items where fingermark residue may have been removed

- Aged prints (proven to develop prints 20+ years old)

- Items that have been previously wetted or submerged

3. Is VMD® a new fingerprint development process?

No. VMD® was first developed by the UK Home Office, Police Scientific Development Branch in the 1970s. However, the old systems were industrial, high maintenance and extremely expensive, resulting in only a few labs worldwide being able to utilise the powerful process.

4. Is the process proven on actual casework?

Yes. The VMD® process has been used operationally by Law Enforcement worldwide for 30+ years. It is classed as a “Category A” fingerprint development technique in the Fingermark Visualisation Manual (1st and 2nd edition) by the UK Home Office – Defence Science and Technology Laboratory (Dstl). This is the highest recommendation awarded!

5. Are forensic VMD® systems expensive?

Thanks to the development of the world’s first benchtop system (VMD360), the costs are less than 1/4 of the price of older VMD® systems. Did you know… You can now buy a forensic VMD® system for less than the cost of some forensic lasers, 360 scene cameras and fingerprint imaging systems!

6. Is the process expensive?

With the emergence of single evaporation metals, a single VMD® process can cost less than $2. This becomes even more cost-effective when processing batches of items, e.g., 20+ fired cartridges, costing merely cents per item.

7. What are the ongoing consumables for the system?

There are no expensive filters to worry about, just the evaporation metals, the source boats (which hold the metal) and occasionally some new oil for the vacuum pump (usually once in every 12 months).

8. How much metal is used?

Very small amounts e.g., approx. 4.4 mg of gold wire (0.25 mm diameter) for the gold/zinc process.

9. How long does a process take?

Typically 5-10 minutes (exhibit and system dependant).

10. Can you process multiple items in a single VMD® process?

Yes, however, we recommend only processing multiple items when they are known to be of the same material type and in the same condition.

11. Is the VMD® process safe?

Yes. Proven to be an extremely safe process and doesn’t require expensive filtration.

12. Does VMD® affect subsequent DNA testing?

Independent research has concluded that VMD® has low interference on subsequent DNA testing, making it a good technique for identifying areas of touch for trace DNA sample collection.

Ref.: Bhoelai, B. et al. (2011). Effect of common fingerprint detection techniques on subsequent STR profiling. Forensic Science International: Genetics Supplement Series. 3, pp. 429-430. Available at: 10.1016/j.fsigss.2011.09.076

13. Does VMD® affect ballistic testing?

No, the VMD® process is non-destructive.

14. Do you need to be a vacuum expert?

Not at all. The new systems are semi-automated and have been designed by Forensic Scientists to be easy to use. Most users are competent within a few hours of training.

15. What system maintenance is required?

All our VMD® systems have been designed to be extremely low maintenance and recommended to be serviced every 1-2 years, if required.

16. What level of ridge detail can be developed?

3rd level – ridge shape/pore configuration.

17. How does VMD® affect the exhibit?

The structure of the exhibit does not change. The amount of metal evaporated will impact the visual look of the item.

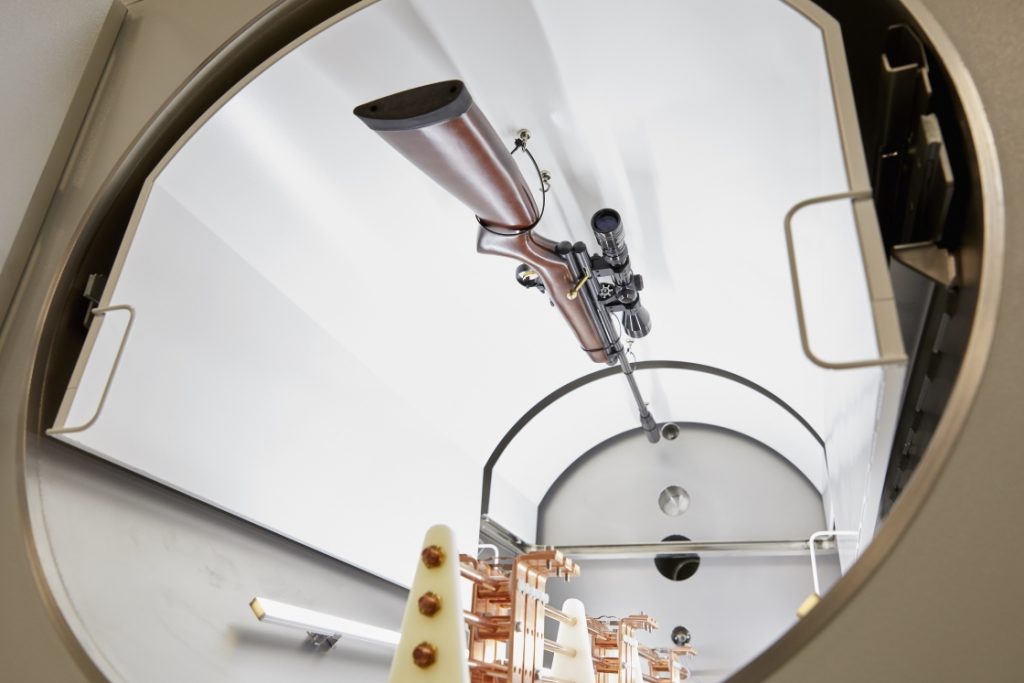

18. What size items can be processed?

The VMD1260 is capable of processing larger items such as rifles, whole trash bags and items of clothing.

19. Does the system come with a warranty?

Yes, 12 months as standard. Extended warranties are available.

20. Which operating languages are available?

The systems operate mostly using icons, however, any text can be translated into different languages, if required.